F600 HP : APPLICATIONS

F600 HP : FEATURES

- Pressure decay leak testing from 5 to 1000 kPa

- Range of measurement from 20 to 175 bar

- 128 programs

- Mechanical regulation 2 MPa/ 5 MPa/ 10.0MPa/ 17.5 MPa

- Electronic regulation 4 MPa

TEST MODES :

- Flow units (sccm, mm3/s, cm3/s, cm3/min, cm3/h…)

- Desensitized Test and others, depending on your applications

ENVIRONMENT :

ROHS standard

FLEXIBLE COMMUNICATION FORMAT :

- RS232: printer, modbus RTU

- Slave USB: PC supervision (WinAteq 300, sesame)

- Master USB: USB key to transfert (parameters, results, …)

- 6 inputs/ 6 outputs 24 V programmable for external automation

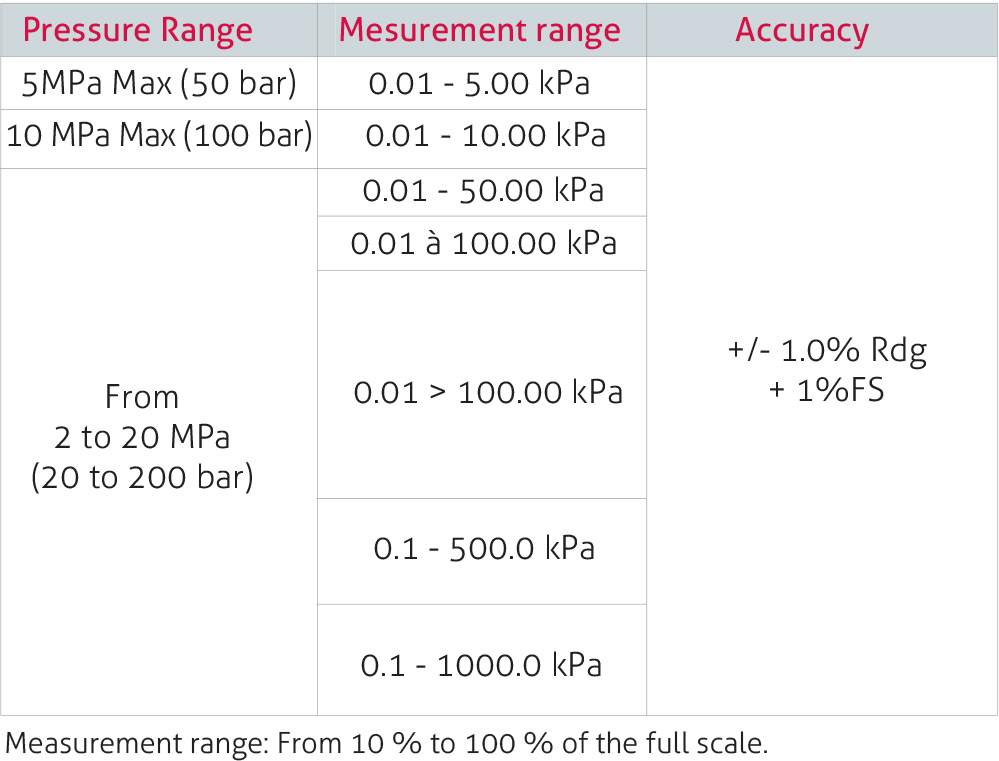

F600 HP : SPECIFICATIONS

F600 HP: TECHNOLOGY

As a stripped down version of the previous technology, standard pressure decay compares the pressure on the part with the atmospheric pressure.

This technology is used when the application does not require a very high accuracy or a very fast cycle time. The method used is based on the measurement of a small variation or drop in pressure with a piezo sensor.

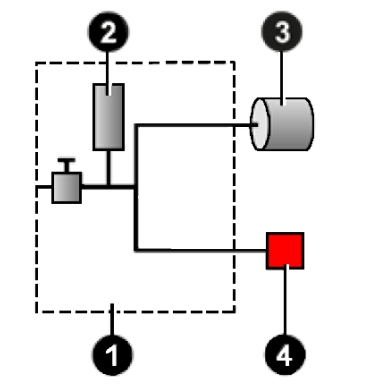

Leak Test & Desensitized Test

The test pressure is applied to the input of the test part 3. The measurement is performed by the pressure sensor 2.

- Device

- Pressure sensor

- Part under test

F600 HP : DOCUMENTATION