TYPICAL APPLICATIONS FOR E-MOBILITY DETECTION EQUIPMENT

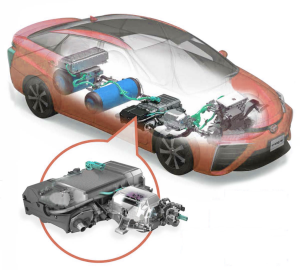

In a hydrogen fuel cell vehicle (HFCV), several components may require leak testing to ensure the safety and efficiency of the hydrogen system:

- Hydrogen tanks: The high-pressure hydrogen tanks store the compressed hydrogen gas onboard the vehicle. CGH2 on-board tank systems are carbon fibre wrapped type IV vessels fitted with safety connections with several sealing and leak-testing challenges. It’s crucial to ensure that these tanks are free from leaks to prevent any potential hydrogen release or hazards.

Main subsystems & components:Tank liner, On Tank Valve, Pressure regulator, Safety shut-off valve, Receptacle, UHP line,…

- Hydrogen fuel lines and connections: The piping and connections that transport hydrogen from the tanks to the fuel cell stack and other components need to be thoroughly checked for leaks. Any leaks in these lines could compromise the efficiency and safety of the hydrogen system.

- Hydrogen fuel cell stack: Manufacturing electrolysers requires the high-throughput assembly and testing of bipolar plates (BPPs) into stack and subsequent integration with BoP components. The fuel cell stack is where hydrogen and oxygen react to produce electricity, powering the vehicle’s electric motor. A fuel cell is a multi-fluidic system composed of the core conversion technology (stack and a diversity of auxiliary equipment) that manage the fluids. It’s essential to inspect the fuel cell stack and its associated components for any leaks that could affect its performance or integrity.

- Hydrogen seals and fittings: A variety of fluid conveyance components are necessary to connect units, with potential leak points at connection interfaces.Main subsystems & components: Connections & fittings, Gas lines & manifolds, Valves, Pressure sensors, UHP connections & fittings,UHP valves

- Hydrogen storage and refuelling infrastructure: If the vehicle is equipped with its own refuelling system or if it interacts with external hydrogen refuelling infrastructure, such as hydrogen stations, these components also need to undergo leak testing to ensure safe handling and transfer of hydrogen gas. Dispensing compressed gaseous hydrogen at 350 or 700bar requires a set of dedicated equipment ensuring high operational safety.

Main subsystems & components: Breakaway, Refuelling nozzle, UHP flexible hoses, Flow meter, Precooling

FUEL CELL BIPOLAR PLATES

ATEQ can provide leak and flow testing solutions for your fuel cell components.

BIPOLAR PLATES

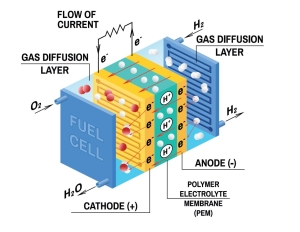

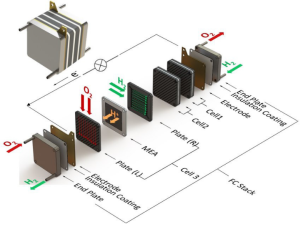

A Bipolar plate is a multi-functional component within the PEM fuel cell stack. It connects and separates the individual fuel cell in series to form a fuel cell stack with required voltage, aids uniform distribution of H2 and oxygen over the whole active surface area of the membrane-electrode assemblies (MEA), conducts electrical current from the anode of one cell to the cathode of the next, facilitates water management within the cell, supports thin membrane and electrodes and clamping forces for the stack assembly, among other things.

ATEQ is the leader for leak testing the 3 main circuits : O2, H2, and the cooling circuit.

FUEL CELL STACK

ATEQ can provide leak and flow testing solutions for fuel cell stacks in e-vehicles.

STACK

A single fuel cell consists of a membrane electrode assembly (MEA) and two flow-field plates delivering about 0.5 and 1V voltage (too low for most applications). Just like batteries, individual cells are stacked to achieve a higher voltage and power. This assembly of cells is called a fuel cell stack, or just a stack.

ATEQ is the leader for leak testing the 3 main circuits : O2, H2, and the cooling circuit.

HYDROGEN TANK

ATEQ can provide leak and flow testing solutions for your hydrogen fuel tank components. .

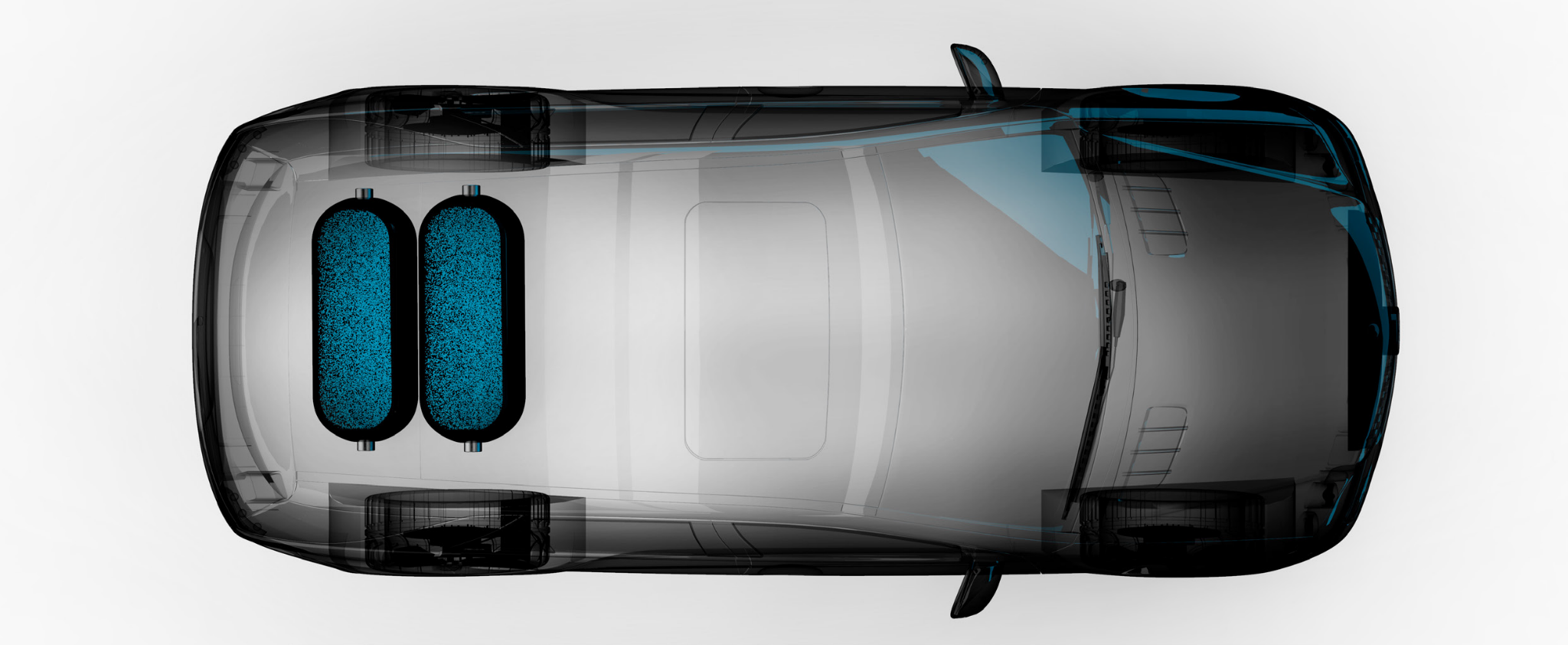

H2 TANK

A hydrogen tank (also called a cartridge or canister) is used for hydrogen storage.

TESTING DURING FINAL ASSEMBLY OF VEHICLE

Besides leak testing the components with our standard line of leak testers, ATEQ also offers testers for final vehicle assembly and the aftermarket.

FINAL ASSEMBLY CAR

Even if all the individual piece are leak tested during the production of the car, it’s also important to the test the final assembly car.

ATEQ: Pioneer in hydrogen (H2) leak detection technology

At ATEQ, we are at the forefront of innovation in leak detection technology.

Our advanced hydrogen leak detection solutions offer fast, accurate detection of even the tiniest leaks.

Designed for a wide range of applications, from automotive to industrial, ATEQ’s hydrogen leak detectors offer complete leak detection solutions.

Hydrogen leak detector

Hydrogen is light, odourless and highly flammable, making it a potentially dangerous element if it leaks from a system or tank. For this reason, rigorous leak test procedures are essential to ensure safety in hydrogen-related applications, such as production, storage and use in the energy and mobility sectors. These tests often include the use of gas detectors sensitive to identify potential leaks, as well as methods of pressure control and continuous monitoring to ensure that systems remain leak-tight. Strict safety standards are also in place to regulate leak testing in the hydrogen field, helping to minimise the risks associated with this promising energy resource.

ATEQ PROPOSES MEASUREMENT, INSPECTION AND TESTING SYSTEMS FOR ALL PRODUCTION SETPS OF THE E-MOBILITY INDUSTRY!

From electrical batteries, connectors, to bipolar plates, ATEQ can support the leak testing tests in a laboratory or production area. Thanks a to huge network of engineers worldwide.

NEW CHALLENGE

If the electrical vehicle market is know well known in terms of leak detection (battery tray, cells, modules,etc), hydrogen is now a resource that is really challenging for the automotive transportation industry, ATEQ is aware of this new opportunity BUT producing, converting, transporting, distributing, and consuming hydrogen requires a variety of systems and components such as electrolysers, fluid conveyance, midstream, refuelling stations, on board tank systems, fuel cells and more…

WHY DO WE HAVE TO LEAK TEST?

Hydrogen is a highly flammable gas, and any leaks in the hydrogen system of a car can pose significant safety risks, including fire or explosion hazards. Leak testing helps ensure that the components of the hydrogen system, such as tanks, fuel lines, valves, and seals, are free from leaks, thereby reducing the likelihood of accidents and protecting all occupants.

In many regions, there are regulations and standards governing the safety of hydrogen fuel cell vehicles, including requirements for leak detection and prevention. By conducting leak testing and ensuring compliance with these regulations, vehicle makers can demonstrate the safety and reliability of their hydrogen cars, gaining regulatory approval for their sale and use.

“Ateq is dedicated to your long-term success”