IONIQ 20

ELECTRIC LEAK DETECTOR FOR HIGH VOLUME PRODUCTION

On the basis of its well proven concept of production line QC Testers, ATEQ has developed a new leak tester designed for the specific requirements of high volume production of plastic parts. This instrument is used for the detection of localized moulding faults, insufficient membrane thickness, perforations, etc. This instrument has also proven to be effective on testing pouch battery cells.

The IONIQ is based on discharge current measurement and is able to detect defects up to of 10µm.

IONIQ 20: APPLICATIONS

IONIQ 20: FEATURES

- Integrated ionising high voltage generator (5 to 27.3 kV)

- Reject levels as % of nominal voltage (0 to 100%)

- Monitoring and protection of high voltage generator

- Limitation of the current rating

- Speed: Minimum cycle time 0.6s

- I/O’s for instrument control and results

- 32 programs

- Remote control allows the test module to be closed to the test part

- Language selection, customization of test …

IONIQ 20: SPECIFICATIONS

IONIQ 20: TECHNOLOGY

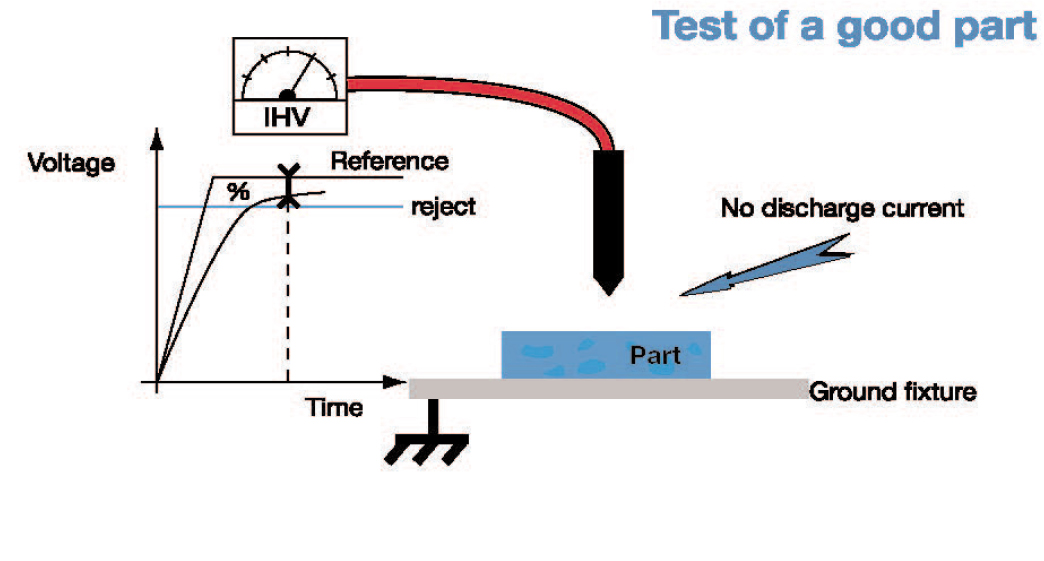

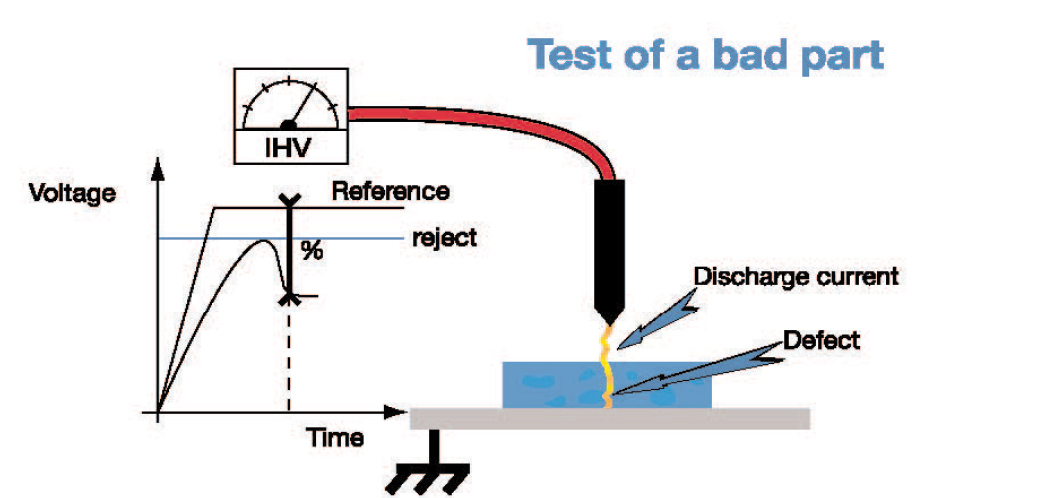

A high voltage loaded sharp end is applied next to an earth connected base and in between lays the plastic part we test. Should a hole exist in the part, ions will start moving from the earth to the sharp end. This will result in a loss of power and be translated into a leak.

While this method does not quantify the leak rate in terms of cc/min for example, it is the fastest ever invented to detect a leak in a go / no go process. We have achieved cycle times of less than 7/10 of a second.

Leak Ranges: Depends on the size of the hole and the material of the part

Accuracy: Depends on the size of the hole and the material of the part

- The IONIQ measures the current flowing between a patented charged probe and a ground plate placed under the part to be tested.

- The IONIQ uses the % of the nominal voltage (which reflects the discharge current), measured on the part as PASS/FAIL level.

- In a PASS situation (fig 1) : No hole, no weak part, the IONIQ measures a high %. The measured voltage and the nominal voltage are virtually equal. The result is above the reject level, the part has passed the test

- In a FAIL situation (fig 2) : The IONIQ measures a low %. The measured voltage is significantly below the nominal voltage. The result is below the reject level, the part has failed the test.

- Test limitations: short probe-part-plate distance, electrical insulation from environment.

IONIQ 20: DOCUMENTATION